Abstract: This paper explores the photovoltaic effect, focusing on key factors affecting solar cell efficiency. It discusses advanced materials and manufacturing techniques that could enhance efficiency. Additionally, the paper presents a solar panel system employing an MPPT algorithm, highlighting its potential in improving solar energy harnessing.

Key words: PV system, MPPT algorithm, Green energy, Efficiency, Photovoltaic cell

Introduction: Solar energy is a renewable natural energy. A photovoltaic cell is the basic component that forms a solar panel. It can absorb energy from solar radiation and convert that energy into electrical energy. It is a one-stem process that relies on quantum theory. The efficiency of this conversion process is critical and has been the focus of extensive research. This paper discusses the latest advancements in materials and manufacturing technologies that significantly enhance solar panel performance. Moreover, due to the I-V characteristic of PV cell, an algorithm that can adjust the output voltage to stabilize the solar panel at its max power point is also important. This article will also demonstrate the importance of MPPT by analyzing a solar panel system.

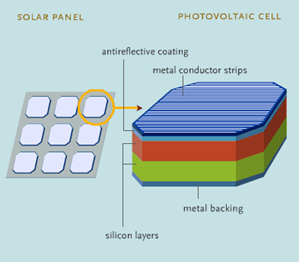

PV panel structure and power generation: The PV cell can be considered as a two terminal device which conducts like a diode in the dark and generates a photovoltage when it is charged by the sun. The most common and traditional form of solar cells is single-junction photovoltaic cell. It is a thin slice of semiconductor. The surface is treated to reflect as little light as possible, so it usually appears dark blue or black. To make electrical contact, a pattern of metal contacts is imprinted on the surface.

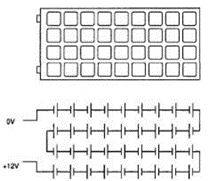

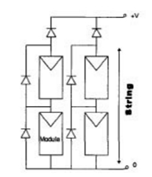

A single cell can only produce very small dc voltage which cannot be used in real life. The cells are connected and encapsulated into modules. For example, to generate 12V dc output, the module should contain 28 to 36 cells. For larger power demand, modules can be connected in parallel and series into an array. In real life, the illumination is unstable and can vary. It is important to connect the solar panel with power regulation and energy storage system.

Reference website: NOVA | Saved By the Sun | Inside a Solar Cell | PBS

A single-junction photovoltaic cell consists of multiple layers. Based on their functions, they can be classified into four layers: protective front layer, anti-reflection coating layer, active material layer and metal backing layer.

The protective front layer of a photovoltaic cell, often known as the glass cover or the encapsulant layer, plays a crucial role in the durability and efficiency of the solar panel. The primary purpose of the protective front layer is to shield the photovoltaic cells from environmental elements such as moisture, dust, and mechanical impacts. This protection is vital for the longevity and reliability of the solar panel.

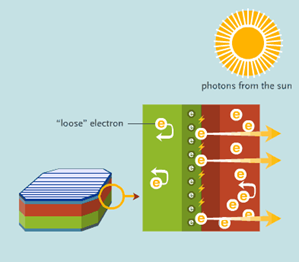

Anti-reflection coating layer is the topmost layer of the cell. Its primary function is to reduce the reflection of sunlight off the surface of the cell. By decreasing reflection, the photons are efficiently absorbed by the active material layer and not get reflected away.

Active material layer consists of N-Type and P-Type semiconductor layer. When sunlight hits the cell, photons knock electrons loose. The n-type layer, having excess electrons, facilitates the flow of these free electrons towards the p-type layer. The p-type layer accepts the electrons that have been knocked loose by the sunlight and moved from the n-type layer. This movement of electrons from the n-type to the p-type layer generates an electrical current.

Metal backing layer, as is indicated, is made of metal with high conductivity (Ag, Al). It serves as the back electrical contact of the cell. It allows for the efficient extraction of the electric current generated in the semiconductor layers.

In general, these layers are assembled in a way that creates the necessary environment for the photovoltaic effect to occur. When sunlight (photons) hits the cell, it energizes electrons in the semiconductor material. The design of the cell, with its n-type and p-type layers, creates a built-in electric field that drives these free electrons in a specific direction, creating an electric current. This current is then captured by the electrical contacts and can be used as electricity.

Latest PV cell technology and market trend: Lots of innovative fabrication methods and materials have been introduced in recent years. For instance, Rajmohan et al. find out a new coating method. They enhance the efficiency of zinc oxide based photovoltaic cells by using Finite Difference Time Domain Technique (Fabrication of Energy Efficient Single Junction Photovoltaic Cell with Nanostructured Zinc Oxide (ZnO) based Antireflection Coating and performance Comparison with Indium Tin Oxide (ITO) based Antireflection Coated Cell). Also, they found out the efficiency with respect to thickness in comparison between ZnO and ITO anti reflection coating configured PV cell. With better anti-reflection coating, the PV cell can absorb more photon and generate more electricity.

Ye et al. measured the efficiency of industrial p-type mono PERC solar cell (22.13% Efficient Industrial p-Type Mono PERC Solar Cell). The passivated emitter and rear cell (PERC) design turns out a promising technology for mass production. That PERC cell they fabricated reach a record of efficiency of 22.13%.

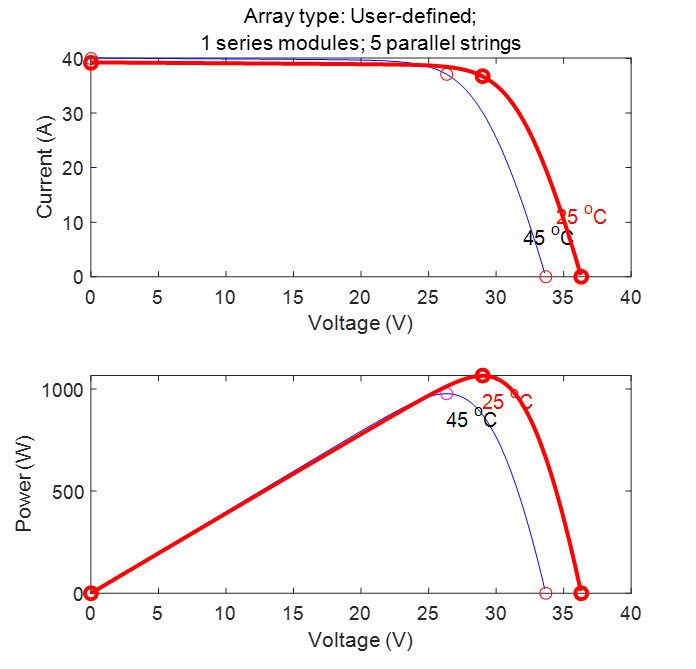

Solar panel system with MPPT: Due to the physical properties of photovoltaic cells, the I-V characteristic of a solar panel is not linear. The surrounding environment can have a great influence on the output of a solar panel. For example, a higher working temperature will generally reduce the overall efficiency of the photovoltaic process. Different levels of sunlight can also make a difference to the voltage output.

As a result, a power control algorithm should be implemented before a solar panel system is put into use.

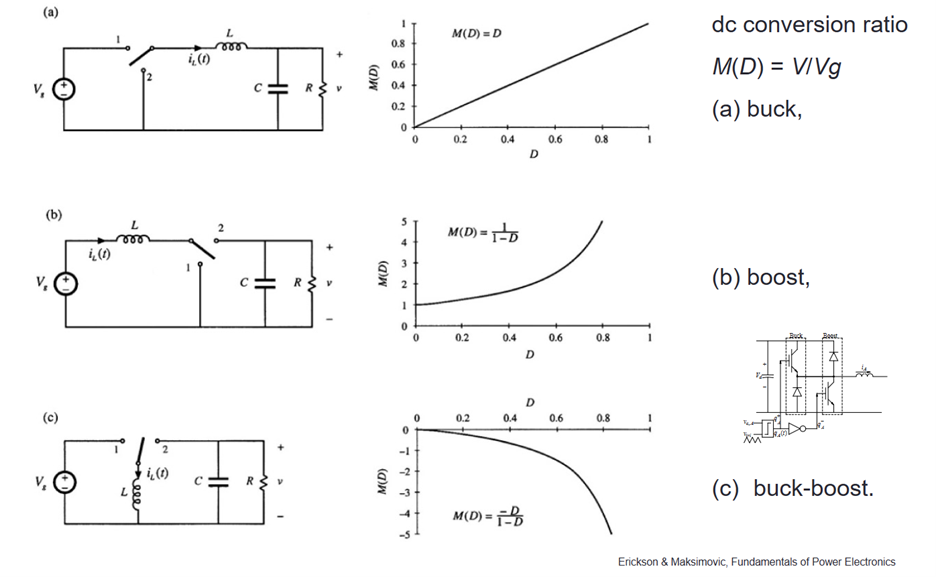

There are three basic converters that convert solar panel DC into industrial/household AC. Buck converter, boost converter and buck boost converter. They are designed for different PV applications.

Buck converter, also known as step down converter, steps down the voltage from its input to its output. It reduces the voltage while increasing the current. Buck converters are used in situations where the source voltage is higher than what is needed by the load. For example, in solar systems, it can be used to lower the panel voltage to suit battery charging requirements.

In contrast, a boost converter (step up converter) increases he voltage from its input to its output while reducing the current. In solar applications, it’s useful for increasing the voltage from a solar panel to a level required by the inverter or load. For example, large scale solar parks in remote areas should use this converter to step up voltage for better transmission.

Buck boost converter combines the functionalities of both buck and boost converters. It can either step up or step down the input voltage depending on the requirement. It’s especially useful in solar power systems where the input voltage can vary significantly. For example, small scale solar panels for homes requires this converter to stabilize the output voltage.

It should be noted that both buck converter and buck boost converter will consume some power in their inductance during the conversion because of the design.

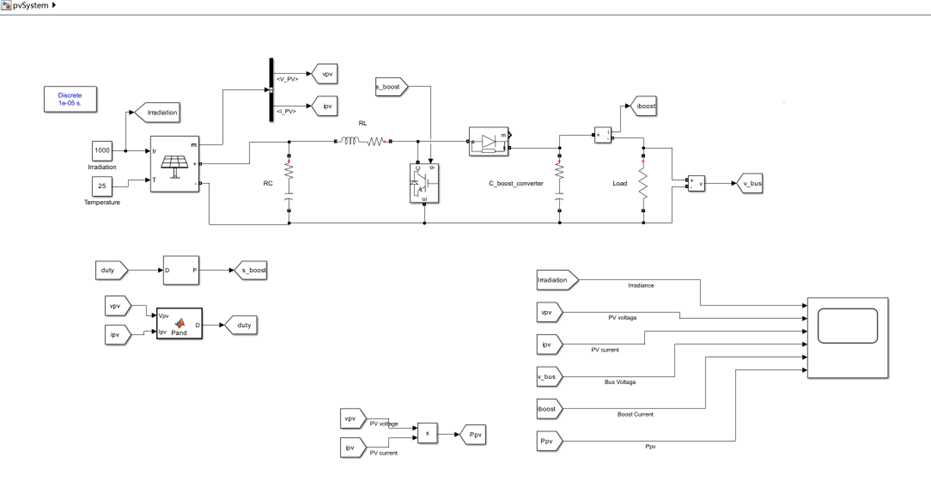

In this paper we use buck-boost converter, converting solar panel DC to AC for household appliances. The full circuit is shown below.

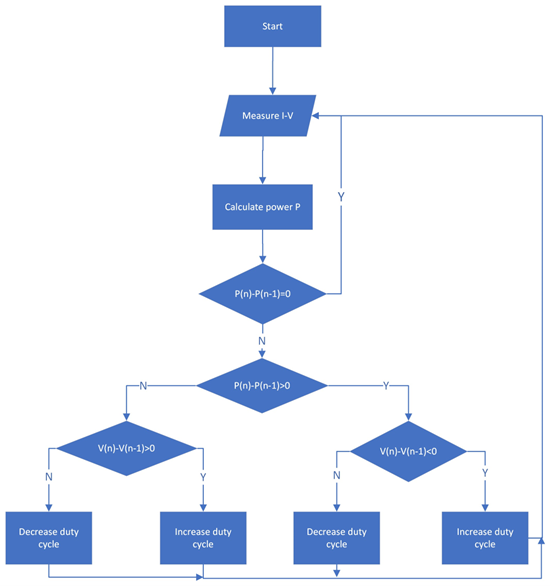

Generally, a maximum power point tracking (MPPT) algorithm is introduced when it comes to solar farm or wind park power optimization. The controller is trying to find the maximum power by comparing the real-time power with the previous power and adjust the output voltage.

If the power is not stable(P(n)-P(n-1) ≠ 0), the controller will first determine if the power is increasing or decreasing. When the power is increasing, the controller will analyze the voltage change. If the voltage is larger, the controller decreases the duty cycle in order to regulate the voltage. There are four conditions in total.

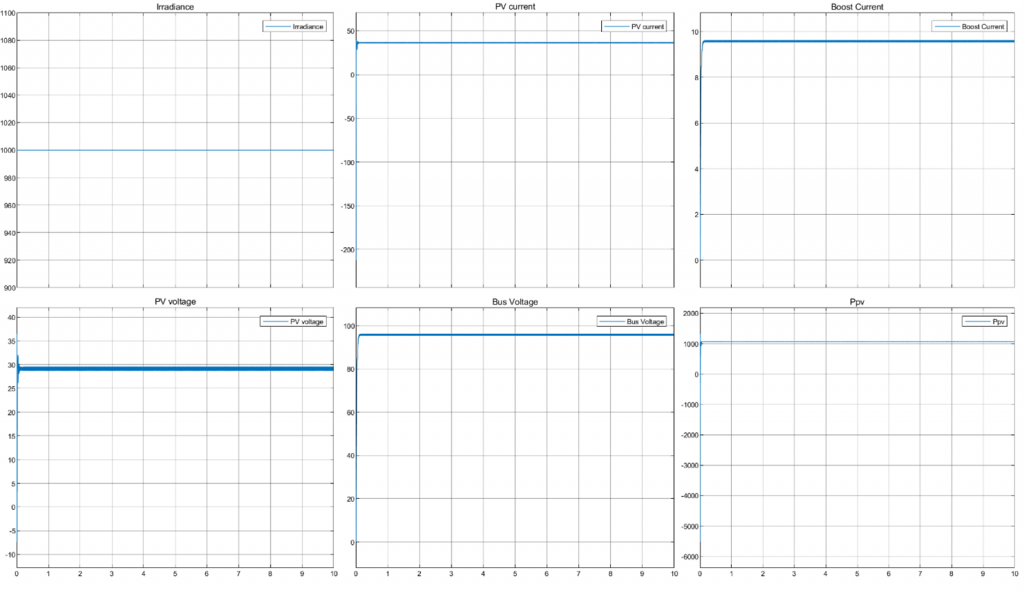

By applying this algorithm, it is seay for the system to operate around its maximum power point. Here are the simulation results.

Conclusion: Driven by the growing demand for renewable energy sources and the need for more efficient and cost-effective solar solutions, the PV cell and solar farm system are promising. As the existing technological process continue to mature, more and more new technologies keep emerging. The efficiency of PV cells continues to breakthrough. Smart and high-performance inverters with better grid support are playing a more and more important role in electricity grid.

MATLAB Simulink File

https://drive.google.com/file/d/1RIthLC2l9IECxHUS3yBud4BhjKj5eNu_/view?usp=sharing